High Performance,Thermally Conductive Gap Filling Material

Typical Properties of TCP200 and Gap Pad® 2000/2000S40 Materials | |||||

Properties | TCP200 Series | Gap Pad A2000 | Gap Pad 2000S40 | Test Method | |

Reinforcement Carrier | --- | Fiberglass | Fiberglass | — | |

Color | Dark Gray | Gray | Gray | — | |

Density (g/cc) | 2.79 | 2.9 | 2.9 | ASTM D792 | |

Thickness(mm) | 0.5 to 4.0 | 0.254 to 1.016 | 0.508 to 3.175 | ASTM D374 | |

Hardness | 25(Shore C) | 80(Shore 00) | 30(Shore 00) | ASTM D2240 | |

Tensile strength(KN/m) | 1.65 | 1.65 | 1.65 | ASTM D412 | |

Operation Temperature(℃) | -40 to 150 | -60 to 200 | -60 to 200 | EN334 | |

Breakdown Voltage(K.v) | >7 | >6 | >6 | ASTM 149 | |

Volume Impedance(Ω.cm) | 6.0×1012 | 1.0×1011 | 1.0×1011 | ASTM D257 | |

Dielectric constant(@|MHz) | 4.5 | 6.0 | 6.0 | ASTM D150 | |

Thermal conductivity(W/m.k) | 2.0 | 2.0 | 2.0 | ASTM D5470 | |

Flame Rating | V-0 | V-0 | V-0 | UL94 | |

Price | Cheaper | Expensive | Expensive | - | |

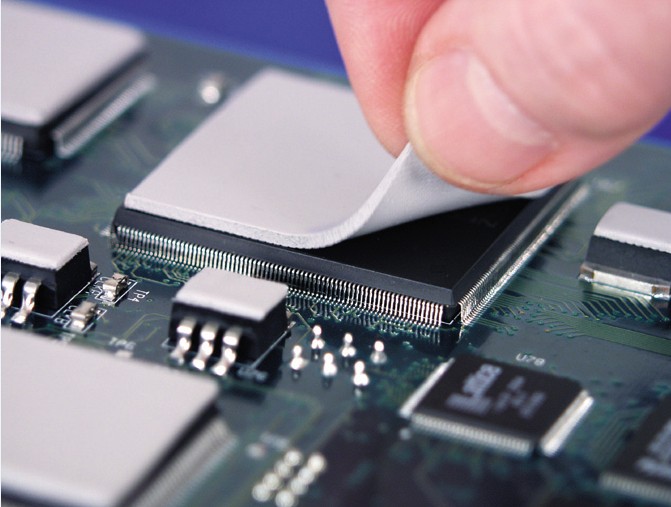

TCP200 Thermally Conductive Gap Filling Material

Gap Pad 2000/2000S40 Thermally Conductive Gap Filling Material

All this type of thermal gap filling materialis recommended for lowstress applications that require a mid to high thermally conductive interface material. The highly conformable nature of the material allows the pad to fill in air voids and air gaps between PC boards and heat sinks or metal chassis with stepped topography, rough surfaces and high stack-up tolerances.