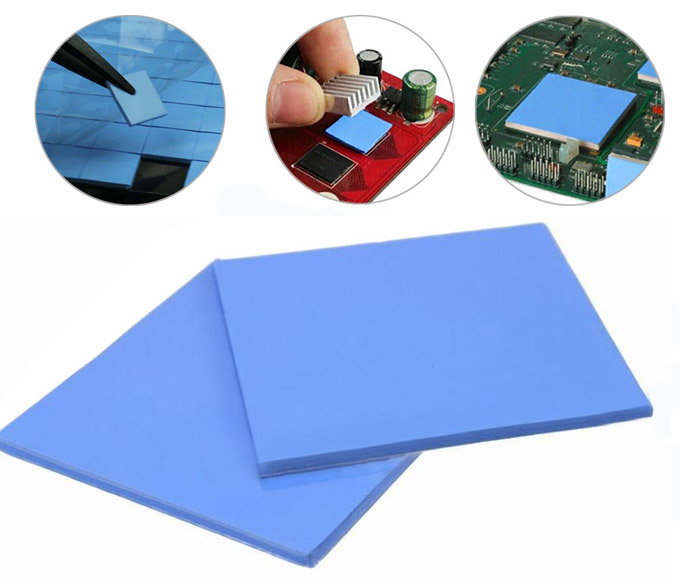

Today we are kicking off a two part series on thermal conductivity and how to use this property to choose a thermal insulators. Thermal conductivity is important since it can help you make the best choice of material for a thermal interface materials. Thermal Pad are often the default choices but are there are other choices of thermal interface materals for heat transfer.

Thermal Interface Materials Experts and Supplier

TIMs Global Market

Wednesday, August 27, 2014

The Insulator Offers The Best Thermal Conductivity for Heat Sinks and Thermal Management Application

Tags:

Published By:admin | Categories:Material Knowledge | Comments:0 | visitors:

Tuesday, April 15, 2014

Material Comparison Test Report

1. Commission Unit: AOK sales Dept.

2. Sample Description:

Tags:

Published By:admin | Categories:Material Knowledge | Comments:0 | visitors:

Thursday, April 3, 2014

The UTP100 Series Thermal Conductive Pad

The UTP100 series thermal conductive pad is made through advanced artificial handling with fiberglass reinforced,which is composed of silicone polymer with ceramic fillers backed thermal conductive pad. The UTP100 is a ultra-soft and exceptional compressive material.It offers excellent thermal performance in close contact with electronic components for effectively lowering the interface thermal resistance. It has natural inherent tack on one side,and works stably at ambient temperature during -40-150 celcius with meeting the requirement of UL94V-0 class.

Tags:

Published By:admin | Categories:Thermal Gap Filler | Comments:0 | visitors:

Thursday, March 6, 2014

Double-sided Thermal Tapes Thermal Characteristics

Double-sided thermal tapes adhere the heat sink to the device and offer good thermal characteristics. They are easy to apply, require no curing time, can be electrically conductive or isolating, and need no mechanical support to provide thermal or physical contact between the device and the heat sink.

Tags:

Published By:admin | Categories:Thermal Gap Filler | Comments:1 | visitors:

Monday, February 24, 2014

Softer Option for SinoGuide's High-Conductivity Thermal Pad

Tags:

Published By:admin | Categories:Thermal Gap Filler | Comments:0 | visitors:

Friday, February 7, 2014

New introduced specially formulated thermal interface pad materials

SinoGuide Technology has introduced specially formulated thermal interface pad materials that simplify board-level maintenance by reducing material tearing during disassembly for re-work and repair. TCP and TC series thermal interface materials feature a unique hardened top surface. This one-sided surface treatment is less tacky than the opposing contact side, allowing the thermal pad material to consistently adhere to either the electrical component or opposing heat sink. The hard surface releases quickly and easily from its component without tearing or damage. TCP and TCI series thermal pad materials are available in seven different formulations and offer thermal conductivity from 1.0 to 7.5 W/m.K.

Tags:

Published By:admin | Categories:Material Knowledge | Comments:3 | visitors:

Monday, January 13, 2014

Thermal Gap Pad Materials Comparation

AOK TP300 Compare with Bergquist Gap Pad® Gap Pad A3000/300s30

Polyester film supported, soft silicone-elastomer with thermal conductivity of 3.0 W/m-K. Conformable at low pressure to minimize stress on components and fill gaps. Good dielectric properties. Handles easily without crumbling.

Tags:

Published By:admin | Categories:Material Knowledge | Comments:0 | visitors:

Monday, January 13, 2014

SinoGuide TCP250 Compare with Bergquist Gap Pad® 2500s20/2500

SinoGuide TCP200 Compare with Bergquist Gap Pad® Gap Pad 2500s20/2500

Thermally Conductive, Unreinforced Gap Filling Material, Gap Pad 2500s20/2500 Alternatives - TCP250

Tags:

Published By:admin | Categories:Material Knowledge | Comments:0 | visitors:

Monday, December 23, 2013

SinoGuide TCP200 Compare with Bergquist Gap Pad 2000/2000S40

High Performance,Thermally Conductive Gap Filling Material

Typical Properties of TCP200 and Gap Pad® 2000/2000S40 Materials |

Tags:

Published By:admin | Categories:Material Knowledge | Comments:0 | visitors:

Monday, December 23, 2013

SinoGuide TP150 Compare with Bergquist Gap Pad® 1500

Sinoguide TCP150 Compare with Bergquist Gap Pad® 1500

Thermally Conductive, Unreinforced Gap Filling Material

Features and Benefits

• Thermal conductivity: 1.5 W/m-K

• Unreinforced construction for additional

compliancy

• Conformable, low hardness

• Electrically isolating

Tags:

Published By:admin | Categories:Material Knowledge | Comments:0 | visitors:

Browse by

Search

Comments and Feedback

Site Statistics

-

- All Posts:42

- ALL Comments:9

- Visitors:4129

- Themes:AOK Global

Web links: Fine Materials | harbermetal.com | thermal pad | thermal pad China